CO2 Laser Machining

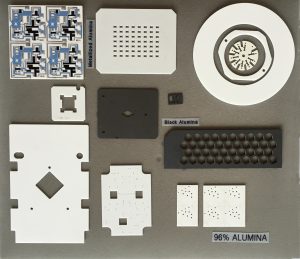

What can you do with a CO2 laser? CO2 Laser Machining has been an essential tool for several industries since the 1980s. Early implementations were cutting holes and shaping the extremely hard electronics grade ceramics beginning to be used for circuit boards that required very high strength and good heat dissipation from the new high powered circuits. Material hardness is not a deterrent for the high energy CO2 laser beam. Almost any two dimensional shape that can be defined can be produced by the CO2 Laser cutter. As the success of the CO2 Laser machines increased, more and varied materials became candidates for this popular tool.

Can CO2 laser cut metal? Although sheet metals have been cut by milling tools for a long time, the CO2 lasers offered many advantages. The very small laser beam (tool) meant that smaller features could be produced. And tool wear is not a problem with CO2 lasers because the tool is a beam of light and does not wear from friction with the metals. Very high temperature metals like tungsten or light weight but tough metals like titanium are good candidates.

The range of materials that are suitable for machining with a CO2 laser has expanded greatly with the wide use of these versatile lasers. What can we do for you?

See our CO2 Laser Processing page for more details of applications.

Leave a Reply

Want to join the discussion?Feel free to contribute!