CO2 Laser Machine/Drill/Scribe

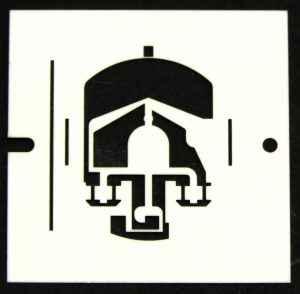

This 1″x1″x.010″ alumina substrate shows the intricate patterns and thin cross sections can be produced by laser machining with a CO2 laser. Many designs incorporate alignment features such as a tooling hole and slot for subsequent processing steps requiring precision, but non-optical alignment. This part is an imaging mask for thin film printing.

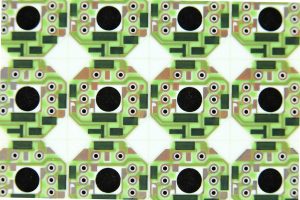

Step and repeat arrays are widely used for gaining production efficiencies during printing. Laser work can be performed before and after the printing steps. The arrays can be laser scribed/scored for final separation.

CO2 lasers are well suited to machining and profiling ceramic substrates for electronics. This is where laser machining services became widespread and therefore helped integrate new materials into electronics.

The CO2 laser is especially powerful for shaping substrates, as well as adding through-holes into electrically-insulating materials that will be used as circuit boards. This is particularly true for high reliability materials used in military and space applications.