Available Services

CO2 Laser Processing

This is really where Laser Machining Services became wide spread and helped integrate new materials into electronics. The CO2 laser is especially powerful for shaping or adding through holes to insulating/dielectric materials that will be used as circuit boards – particularly high reliability materials for Military and Space applications.

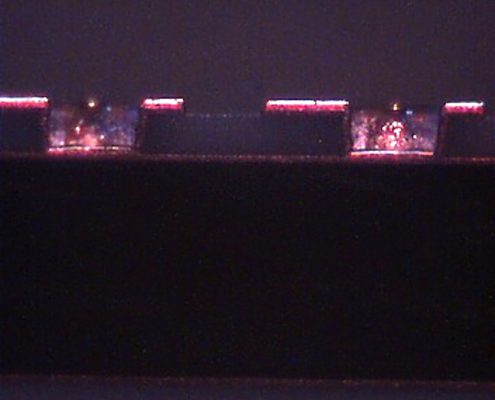

UV/IR MicroVia Laser processing

The UV Laser is well integrated into Laser services now – due to its very small beam spot-size, material ablation abilities, and low thermal input. High density and high Via counts? No problem for our lasers.

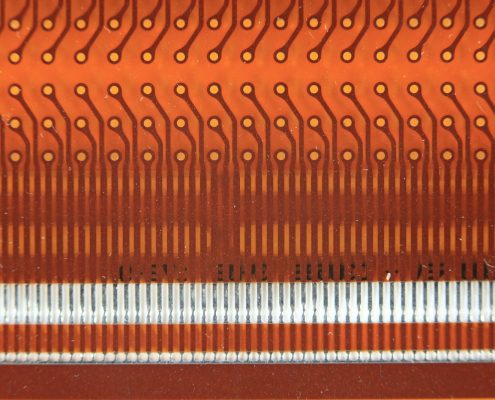

PCB laser processing services

Much of the printed circuit board (PCB) work done in the USA is quick turn around or prototype design work and thus is well suited to the laser’s flexibility and accuracy. This work is often a combination of Infrared and UV lasers.

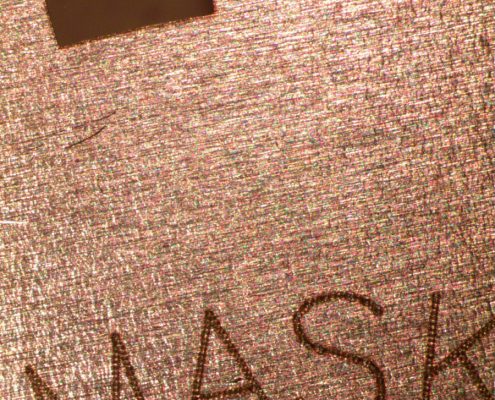

Laser Marking

Tracking for sensitive components as well as the need for ease of assembly are becoming more common. As a result, laser marking can fulfill your permanent part number and or serial numbering requirements.

Multi wavelength lasers

Accu-Tech brings multiple laser wavelengths to the table in order to best approach the materials you need processed. We have three Infrared wavelengths and Ultraviolet to cover a wide range of requirements.

Quick turn options

We know that not all orders come in with due dates scheduled weeks or months out. We have streamlined our organization to handle fast turn around when needed. Our facilities include backup equipment and monitoring to minimize downtime.

Alumina clean firing and annealing

Some electronic ceramics require laser cut surface restructuring. Similarly, some ceramic materials go through later steps that require all organics to be removed by a high temperature clean fire operation. Accu-Tech has high temperature furnaces to accommodate these requests.

Accu-Tech is your source for quality laser services. This includes laser machining or marking your materials, but laser services also include the ability to clean fire the laser cut parts to assure the materials are returned free of organics, if needed. Accu-Tech Laser Processing, INC has been providing laser services to the aerospace and defense sectors for over thirty years so you can depend on our knowledge, expertise, and teamwork to see your project through. We can offer suggestions and guidance during your prototyping phase so that our laser services meet your expectations. We supply Certificates of Compliance (CofCs) with all non sample orders after the parts go through a careful final inspection. Besides our home turf of North America, we ship to the UK, EU, Asia, and the Middle East. With modern shipping, our laser services can have a far reach and quick deliveries.

If you have any questions about any of our services – Click this link to our Contact Us page!